Process Thread Rolling

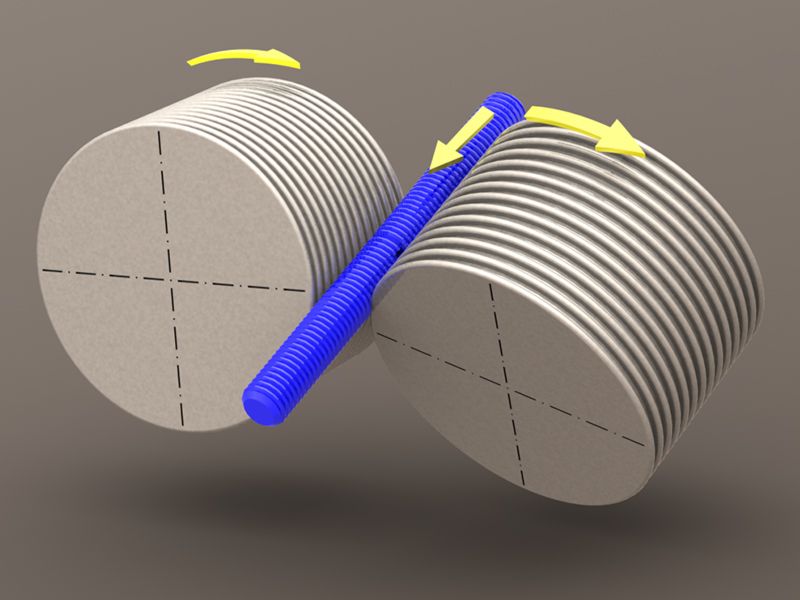

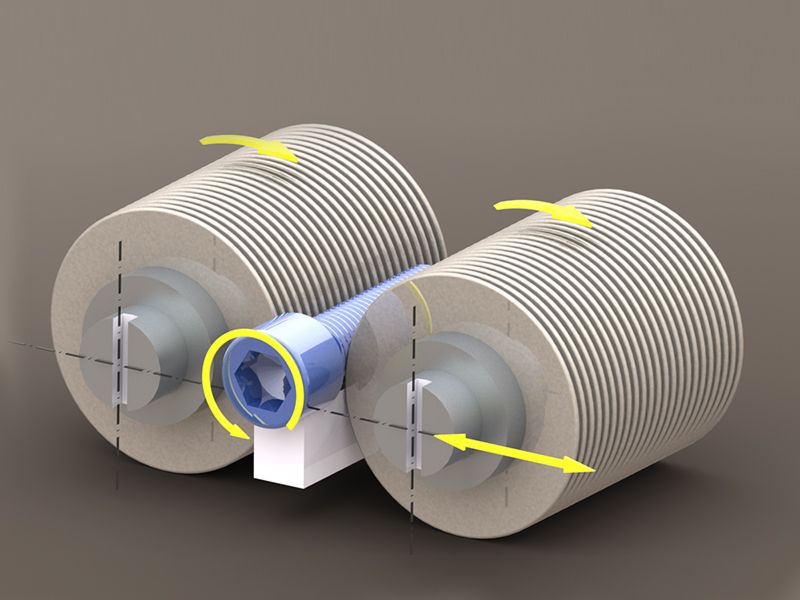

Thread and Profile Rolling belong to the chipless forming procedure. This technology is used for producing threads, worm gears and serrations on the outside of a round work piece which is axially symmetric. On the sur- face of the work piece a certain profile will be formed.

This is an extremely efficient chip - less forming process saving steel because of the absence of chips on the one hand. On the other hand you will receive an increase in the surface hardness . Based on the uninterrupted structure in the cold formed material you will receive a work piece of in- creased tensile strength.

Application:Standard threads, special threads, knurling, ball screws etc. medium to high accuracy

-

Production rate: 1 to 60 m / min

-

Work piece sizes: M2 upt to M 300 in standard or high tensile steel length up to 6000 mm

Application: Standard threads, special threads, knurling and serrations with medium to high accuracy

-

Production rates: 1 up to 300 Teile / min

-

Workpiece sizes: M2 bis M 300 in standard or high tensile steel

-

length of the thread/serration = width of the tool

- Thread Rolling Machines

- Spline Rolling Machines

- Planetary Thread Rolling Machines

- Cold Forming by Profile Rolling Machines

- Tooling

- Process Thread Rolling

- Centerless Grinding Machines

- Overhauling

- CNC Gewindeschleifmaschinen

- Reishauer Service und Reishauer Gebrauchtmaschinen

- E-SLIDE - Rolling Machines